Fabrications and Welding Merseyside

Here at SGG Environmental we have a well-equipped H.D. Polyethylene fabrication department. We have state of the art equipment in house including a workshop Butt fusion welding machine, extrusion welding guns, rod welding units, socket welding irons and other associated components.

We can supply bespoke fabrications to your specifications or please just inform us of your specific requirements and we will work with you where possible to provide a suitable best cost option.

Please note that we can also work with L.P.D.E., Polypropylene and other polymers utilising our equipment, but this may not be cost effective as we do not undertake works with these as standard.

Our principal fabricator and others associated have over 50 years combined experience working with Polyethylene and other plastic fabrications. This is from working within SGGESL and previous employers. Our principal fabricator is fully trained in all aspects of plastic welding and has over 30 years hands on experience. He was trained in the U.K. at Fusion and in Germany at a Bauku facility.

Services provided include:

Butt Fusion Welding

• Linear butt fusion welding to 315mm. (Possibly upsize and hire in if required).

• Angled butt fusion welding to 315mm.

• Tee butt fusion welding to 250mm.

• Angled tee butt fusion welding to 250mm.

• Cross butt fusion welding to 250mm.

Many other, more complex fabrications, which incorporate combinations of these elements, are available upon request.

Extrusion Gun Welding

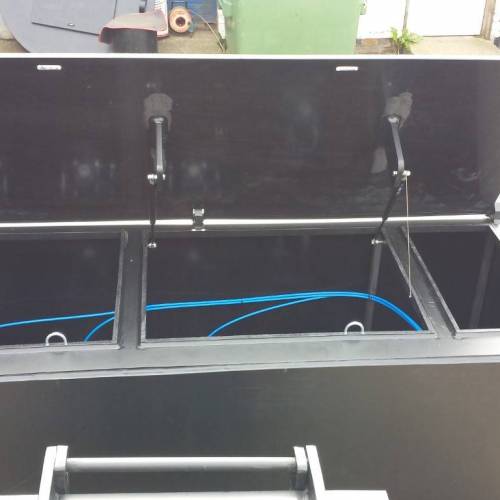

Generally used for low pressure fabrications such as: Wellheads, condensate knock out pots, manifold boxes, complex angles, nonstandard pipe joints, enclosures, boot details, holding tanks and storm water retention tanks.

Rod Welding

Generally used for light duty welding for low pressure applications but can be “built up” to achieve a more substantial joint.

Other Works

We do not just supply fabrications and undertake repairs for the Landfill and Landfill Gas industries.

We endeavour to aid any that may wish to utilise our services. At one extreme, we have provided fabrications and repairs to existing fabrications for commercial clients working with certain alkalis and acids, and at the other extreme, to members of the public who were working with rain or saltwater.

If what you need requires some previous experience, we may well have it.

One unusual repair was on a low-pressure water tank on an antique vehicle. Part was irreplaceable, several years later this vehicle is still running and being exhibited.

Typical fabrications:

• Well heads for various uses, including fittings for monitoring, pneumatic pump installations and electric pump installations.

• Manifolds; both boxed and free standing.

• Butt and extrusion welded joints.

• L.F.G. condensate into waste drain units (Expansion vessels and lances).

• In-line condensate knock out pots and off-line condensate knock out pots, both barometric and non-barometric.

• Enclosures.

• Silt and solids traps.

Please note that this is not an all-inclusive list. If you require any other type of fabrication, please contact us and we will endeavour to fulfil your needs.

We can also supply the majority of other components you may require for your installation at competitive prices.